Whitebird F00

Double Group

Mechanics

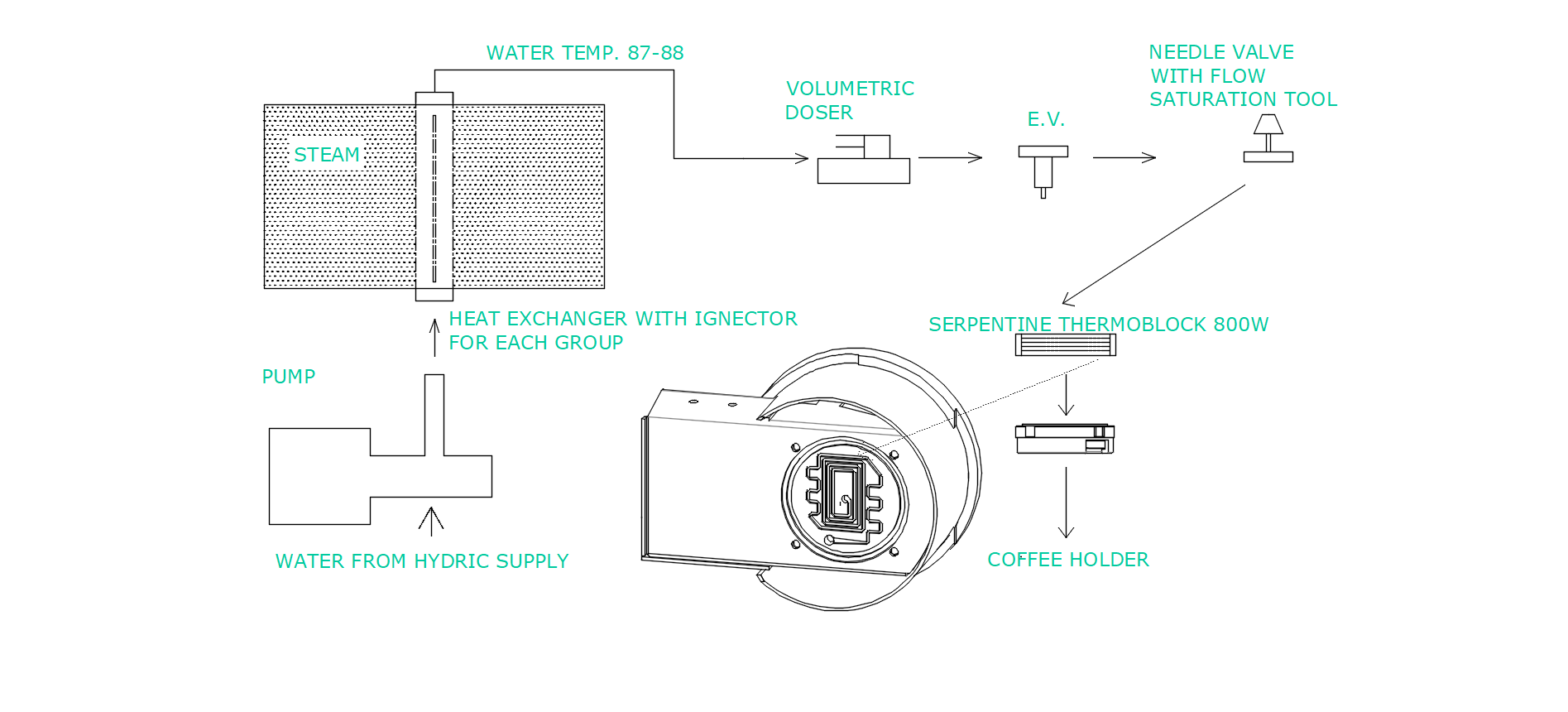

Our models are built on a dual boiler system.

An internal boiler that generates steam and pre-heats the water to 87-88 degrees with vertical heat exchangers with ignectors inside.

On the dispenser group there is a coil system with dry resistance which instantly heats the water from 88 to 99 degrees.

It is possible to set the temperature of the steam boiler and the groups, as well as the on/off option independent.

There are flow regulators behind each group and a device in the external pump that allows you to perform ramp up / ramp down pressure bending profiles.

There is also a timer for each group which displays the dispensing time.

We can adjust the temperature of all boilers (inside boiler and groups boilers) with a temperature deviation of 0.4 degrees over 60 seconds of brewing.

We have eliminated 99% of metals that are harmful to health present in coffee machines; reinforced teflon food contact tubes, 304 stainless steel, lead-free brass and anodised corner-resistant aluminum.

The two groups, is built with automatic volumetric dosing technology with a silicone button panel, as well as all the flow and pressure controls.

It is possible to program the doses, enable or disable the electronic pre-infusion and dispense in free mode without volumetric dosing.

We have integrated a software into the control unit that compares the delivery time and the volumetric dose in relation to the weight; if these two factors do not go hand in hand, the keyboard will start flashingind icating a probable machining or water flow setting error.

Our custom software can also replicate the working system of the paddle machine;

by starting the brewing, the machine works in these steps:

– pre infusion at low pressure (0-2 bars) by opening the electro valves (3 seconds, not editable but can be abled-disabled)

– infusion with pressure, flow and curvature profiling

It is possible to have “free” manual brew without dosing, by clicking free brew mode button.

Also temperature control, steam temp. Control, on/off option for all boilers.

2 group tech

- width mm 524

- lenght mm 800

- height mm 439

- boiler 4.5 litres for steam and 1 litres for group

- volt 380/400

- boiler heating 3.55 kw

- pump 0.184 kw

- boiler pressure 1.0 -1.2 bar

- security valve pressure 1.8 bar

- heat exchanger pressure 10.0 bar

- security valve heat exchanger 11.0 bar

- pressure brew – adjustable max 10 bar

- group heating 1,6 kw